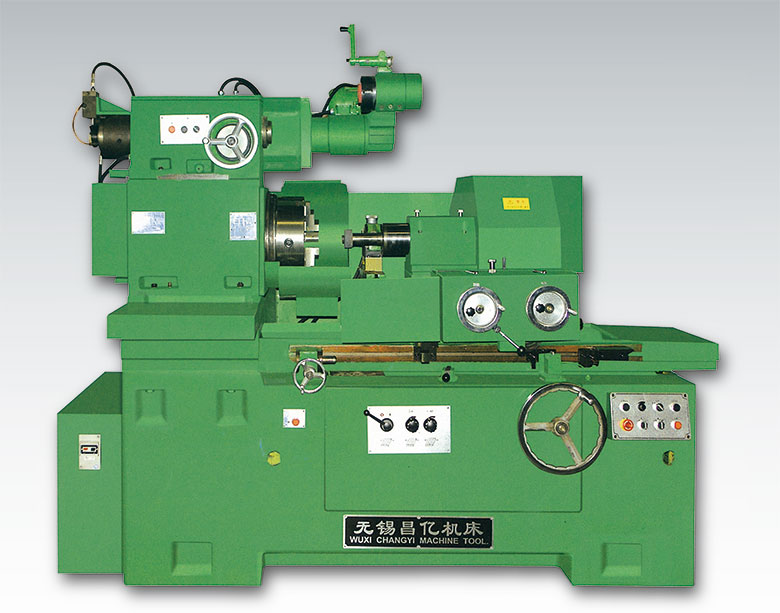

main feature:

1.The feed and correction of the machine tool are carried out by two transmission mechanisms that do not interfere with each other. The feed system has a fixed-range grinding function, which adopts two kinds of feed modes: manual or hydraulic.

2.The machine tool is equipped with a fast-jumping mechanism, so it is not necessary to re-tool manually after exiting the grinding wheel for measurement or correction.

3.Workbench starts with hydraulic on-off valve to ensure immediate safety of loading and unloading workpieces.

4.When the machine is specially ordered, it can be equipped with a high-speed grinding wheel shaft of 1800 rpm, which is suitable for grinding requirements of 20-50mm holes.

5.The machine is equipped with an end grinding device, which can grind the inner hole and the end face in one time, and ensure the verticality of the inner hole and the end surface.

Specification table

| Machine model |

MD2120 |

| Grinding aperture(mm) |

φ50-φ200 |

| Maximum grinding depth(mm) |

200 |

| Workpiece diameter(mm) |

Inside the cover(mm) |

φ400 |

| Outside the cover(mm) |

φ600 |

| Machine head maximum turning angle(°) |

30° |

| Workpiece speed(r/min) |

100-500(Stepless) |

| Wheel speed(r/min) |

4000-6000、8000-11000 |

| End speed(r/min) |

1500 |

| Total machine power(kw) |

8.6 |

| Workpiece motor power(kw) |

2.2 |

| Grinding wheel motor power(kw) |

4 |

| Machine dimensions(mm) |

3100×2120×1320 |

| Machine weight(kg) |

3400 |

| Working accuracy |

Inner hole roundness(μm) |

3 |

| Inner hole cylindricity(μm) |

8 |

| Inner hole surface roughness(μm) |

Ra0.63 |

|